BMW Plant Leipzig: Sustainability Pioneer

The BMW Plant Leipzig, which opened in 2005, is one of the most modern and sustainable car factories in the world. It is also a pioneer when it comes to electromobility: the BMWi3, the world's first premium vehicle designed from the ground up for electric drive, was launched on the road from here.

Infomodul

Facts about the BMW plant in Leipzig

-

March 2005

Start of series production -

About 6,800

Employees (2024) -

More than 5,000 million euros

Total investment ammount -

246,195

vehicles produced (2024)

milestones

The history of BMW automobile production in Saxony began in 2001. The Bavarian car manufacturer was looking for a European location to manufacture its planned 1 Series. Leipzig was chosen from a selection of 250 locations. The combination of many positive factors, such as the industrial experience of the people in Saxony, the developed infrastructure, the opportunities for creating flexible structures, and the favorable location within the network of BMW production sites, were the deciding factors.

The groundbreaking ceremony took place in 2002, and series production began in 2005. Currently, four models with three drive systems from two brands are being produced on one production line at the BMW Group plant in Leipzig: the BMW 1 Series, the BMW 2 Series Active Tourer (also as a plug-in hybrid), the BMW 2 Series Gran Coupé, and the MINI Countryman with fully electric and conventional drive systems. When planning the plant, production was calculated at 650 units per day. Twenty years later, the number of possible units per day is up to 1,300. Since 2005, there have been 20 product launches with BMW and MINI vehicles "made in Leipzig." Since the start of series production, around 3.75 million vehicles (as of March 2025) have been manufactured in Leipzig.

The BMW Group has already invested a total of more than four billion euros in the site to date.

BMW Plant Leipzig

Sustainability in Production and Product

The investment not only helped to continuously expand and modernize the production capacities in the pressing plant, car body shop, paint shop, and assembly line. BMW also meets the objectives which the company has pursued in Leipzig right from the start; namely, to advance and promote the topic of sustainability in a holistic and comprehensive approach. This is best exemplified by wind turbines, a battery storage farm for the secondary use of worn-out e-vehicle batteries and energy-efficient processes as well as by pilot projects revolving around the use of hydrogen in production and logistics.

One of the plant's landmarks are the four wind turbines, visible from afar, which have been supplying green electricity to the production facility since 2013. The wind turbines have a total output of 10 megawatts and produce approximately 26 gigawatt hours of electricity from wind energy per year. This covers around 15 percent of the plant's total electricity requirements.

In addition, the plant can temporarily store electricity in a storage farm that began operating on the plant premises in 2017. Up to 700 high-voltage batteries from BMW i3 vehicles are being reused there. The facility can thus optimize local energy management or contribute to grid stabilization.

Looking to the future, the BMW plant in Leipzig is focusing on hydrogen as an energy source. The vision is to achieve extensive decarbonization of production, i.e., replacing fossil fuels with hydrogen. This requires sufficient availability via the grid. The Leipzig plant has the opportunity to use a hydrogen network that is being developed in the region for this purpose.

The Leipzig plant has over a decade of experience in using hydrogen in internal plant logistics and is a pioneer in the automotive industry. In 2013, Germany's first indoor hydrogen filling station was built, and there are now five of them. Forklift trucks and tugger trains for intralogistics are refueled there. The fleet of over 200 fuel cell-powered industrial trucks is one of the largest in Europe. BMW is also relying on Saxon expertise in the further development of these drive systems. Together with the vehicle developer FES from Zwickau, driverless transport systems powered by hydrogen fuel cells are being developed.

In addition, the plant is the first automotive plant in the world to use a newly developed bivalent burner technology in its paint shop that can run on either natural gas or hydrogen. It is even possible to switch fuels during operation. Five burners used to dry the contrasting roofs for the MINI Countryman, BMW 1 Series, and BMW 2 Series Gran Coupé models can be operated with natural gas or hydrogen. Another six burners in the PVC drying section of the paint shop have also already been replaced for dual-fuel use with hydrogen or natural gas. With the pilot operation of the dual burner, the plant is testing the feasibility of reducing the CO2-intensive use of natural gas as a fossil fuel. A prerequisite for the continuous use of hydrogen is the sufficient availability of green hydrogen via pipelines.

The BMW Group plant in Leipzig is planning to connect the site to a hydrogen pipeline. The plant is thus setting the course to become the world's first automobile production site to be supplied with hydrogen via a pipeline. To this end, a contract was signed in October 2025 with partners MITNETZ GAS GmbH and ONTRAS Gastransport GmbH. BMW commissions MITNETZ GAS to construct an approximately 2 km long connection pipeline from the plant to the future hydrogen core network, including a gas pressure regulating and measuring station. BMW and ONTRAS agree on the corresponding grid connection. The connection pipeline is expected to supply the plant with hydrogen from mid-2027.

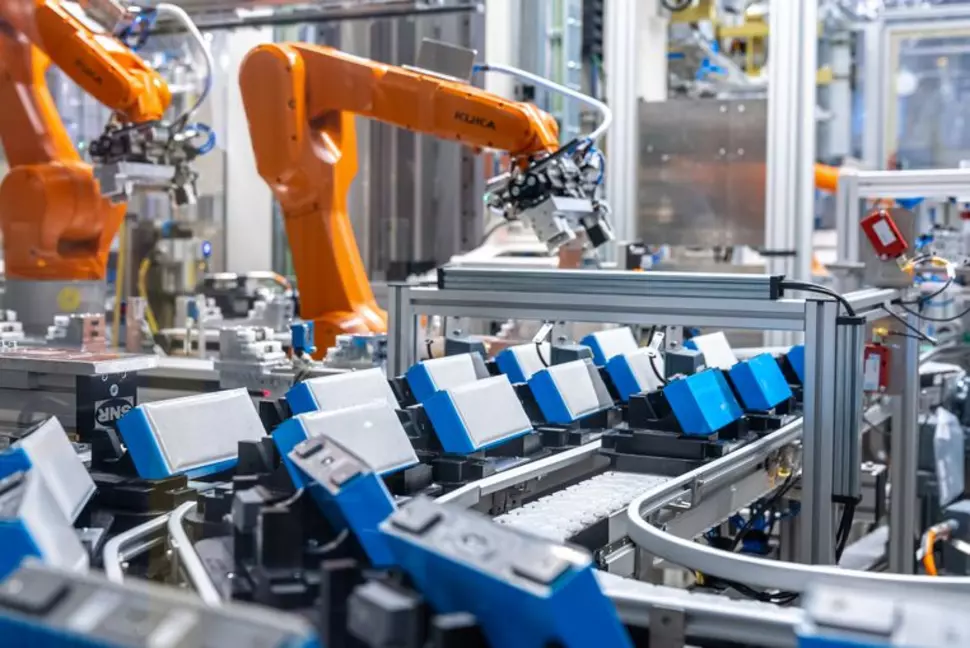

Production of High-Voltage Batteries

When it comes to accelerating sustainable mobility, BMW underpins the pioneering role of its Leipzig production site with the latest investments. For an amount of 800 million euros, the automobile manufacturer is expanding the production of battery components in Saxony. The vacated floor space of the former i3 production as well as the extensive experience of the staff gained from e-vehicle production all provide the best possible prerequisites here. A total of ten new production lines will be set up by 2024, which include three battery module lines, five lines for the coating of cells as well as two high-voltage battery assembly lines.

Part of the high-voltage batteries made in Leipzig are used directly on site because they are built into the fully electric Mini Countryman which will be manufactured in Saxony as of 2024. This will be the first Mini model to be built completely in Germany. The new crossover model of the Mini brand will leave the assembly line in Leipzig both with a combustion engine and a fully electric drive. Thus, the Saxon factory demonstrates once again its high flexibility. It is the first factory where vehicles of the BMW and Mini brands are produced together. The systematic orientation towards comprehensive and holistic sustainability was one reason for the company to locate the production of the new Mini Countryman in Leipzig.

From 2028: BMW to use eFuels for initial filling

The BMW Group, German eFuel One GmbH, and Lother GmbH have signed an agreement to fill new BMW vehicles with gasoline engines with synthetic gasoline for the first time starting in 2028. With this decision, the automobile manufacturer is making a clear commitment to technological openness and the further development of efficient combustion engines.

The basis for this progress is provided by CAC ENGINEERING from Chemnitz with its CAC MethaFuel® technology. The process uses CO₂ and green hydrogen to produce synthetic gasoline that can be used in existing engines—without any modifications to the vehicles or infrastructure. The prerequisite is the implementation of a large-scale industrial plant for the production of this climate-friendly fuel—investor talks are already underway. The corresponding demonstration plant with CAC technology has been in operation for 15 years on the premises of the TU Bergakademie Freiberg.