Closing Automation Gaps with "Swarm Intelligence"

The Siemens Group, the Chemnitz-based 3dvisionlabs GmbH as well as the Dresden-based Robotron and Wandelbots corporations have joined forces to develop the so-called “RoboSpector:” A mobile robotic cell which supports companies in implementing new automation projects.

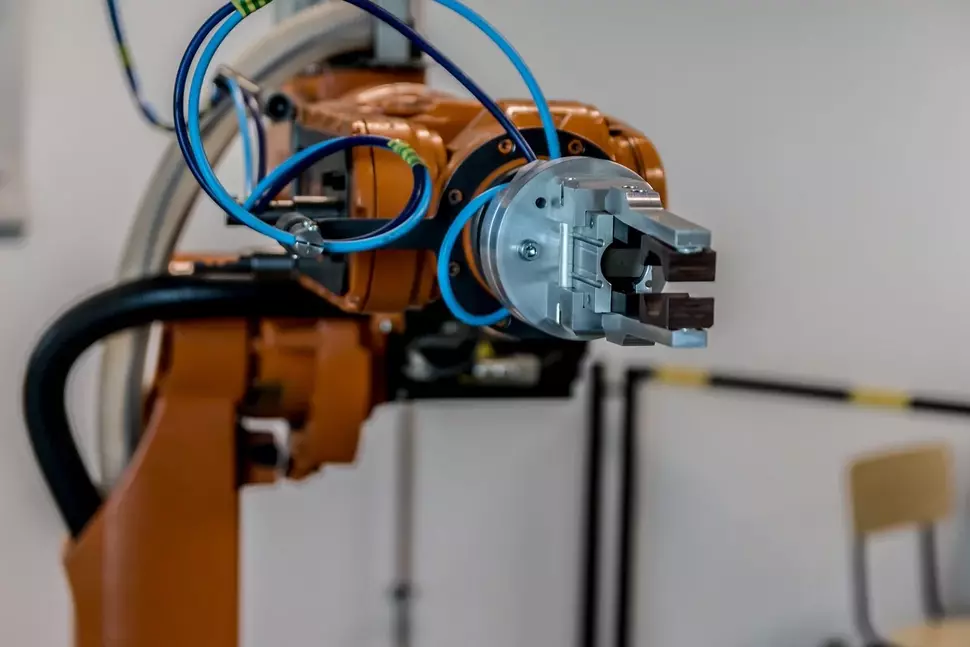

To develop innovative robotic solutions, powerful corporate groups, medium-sized technology enterprises, and startups cooperate closely with one another in many places in Saxony. Towards this end, they often apply the swarm intelligence principle by establishing temporary cross-company development teams. For example, the Siemens Group, the Chemnitz-based 3dvisionlabs GmbH as well as the Dresden-based Robotron and Wandelbots corporations have joined forces to develop the so-called “RoboSpector:” A mobile robotic cell which supports companies in implementing new automation projects. “This system permits engineers, technicians, and other experts to quickly use new – particularly temporary – industrial robotic solutions for their processes without having to rely on automation and robotics specialists,” Dr. Patrick Grosa, Head of Business Acceleration at Wandelbots, sums up the opportunities the artificial robotic inspector provides to the companies where it is used.

The initial idea for the cooperation between the Siemens representatives and the robot teaching specialists of Wandelbots came about during an entrepreneurial meeting in Saxony. Both the corporate group and the startup recognized the opportunities that might arise from such a cooperation. An ap-plication scenario unfolded quite quickly: Today, Siemens uses the robot teaching pens known as “TracePens” from Dresden for the professional training of its personnel in Chemnitz. A focus here is on the various possibilities of automating gluing and bonding processes with robots.

But it just didn’t stop there: During numerous pilot projects in the companies of industrial partners, the Wandelbots experts identified the unused potentials that are still available in the application of robotics in many places. Just installing prototypes of robots again and again and equipping these robots specifically for the respective purposes is not very effective; especially if many other points of use are foreseeable on the customer’s premises. In a nutshell: A comprehensive mobile solution, a driving robotic cell emerged as a viable solution.

Siemens AG’s Systems Engineering Plant Chemnitz (WKC) manufactured the cell and the superstructures for this “RoboSpector.” Robotron Dresden contributed the requisite solutions for computer-based image analysis (computer vision) and artificial intelligence (AI). 3dvisionlabs, in turn, spe-cializes in cameras into which such AI models can be embedded. And the overall concept, the teach-ing technology as well as the interfaces between the diverse systems came from Wandelbots. The mobile lightweight robot is equipped and coupled with everything that is needed for work that is mostly autonomous: With image sensors, a monitor, decentralized evaluation electronics, its own power supply, numerous interfaces, cloud connections, and the like.

Currently, the “RoboSpector” is still in the prototype phase. But the partners anticipate great market opportunities with their innovation: “Our solution will help companies integrate new quality and conformity inspections into their production lines in an extremely agile manner, teach their robots without any programming skills, and deploy their robots flexibly anywhere on the corporate premis-es,” emphasizes Robotron’s Michael Baling.