Fast and Precise with the Laser

When it comes to production engineering, answers to such challenges as the energy and mobility transition are provided by the LASERVORM GmbH in Altmittweida. Founded in 1994, the company has become a specialist for the construction and job order production of laser machines and systems.

LASERVORM possesses comprehensive knowledge specifically in laser welding, laser hardening, and laser cladding. Thanks to the combination of technological expertise and competencies in production and mechanical engineering, the corporate team of about 70 employees is able to offer complete, application-oriented solutions for various types of material processing with lasers.

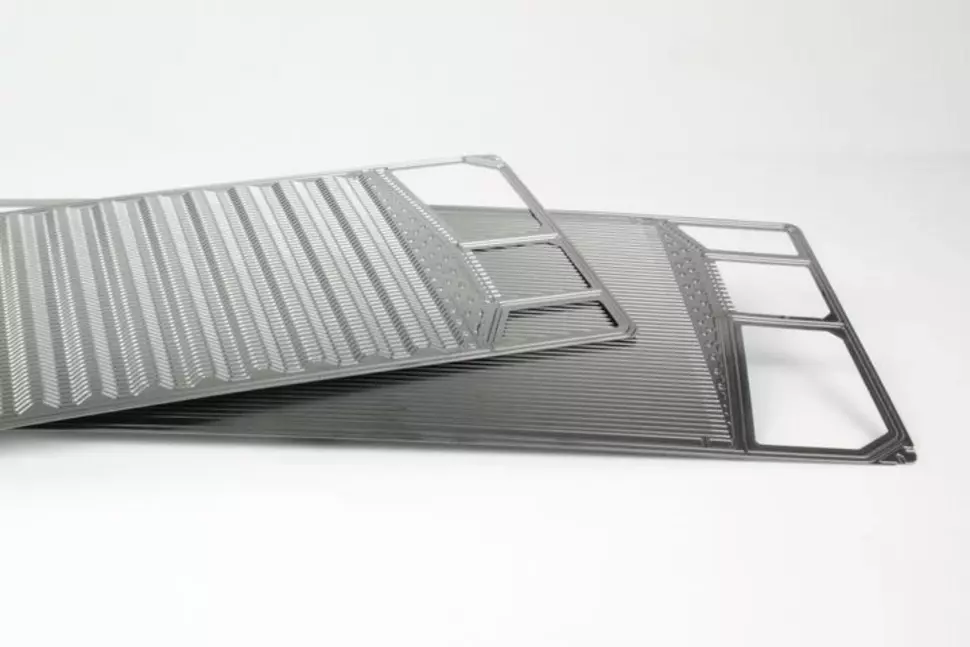

The high-precision and, at the same time, ultrafast joining of diverse materials is indispensable particularly for the efficient production of high-performance batteries, heat exchangers, or fuel cells. For this purpose, LASERVORM has implemented a high-speed laser welding process. With a feed rate of one meter (which translates into 3.28 feet) per second, the procedure permits the welding of ultrathin stainless steel foils such as those which are required, for example, for the production of metallic bipolar plates. These plates form the mechanical main structure of fuel cells. With its extensive process and plant expertise, LASERVORM helps make these production processes suitable for mass production. Towards this end, the company cooperates closely with partners from the Innovation Cluster “Wasserstoffland Sachsen” [Hydrogen Land Saxony].

The company masters high-speed laser beam welding not only when it comes to the joining of metallic materials, but also the joining of plastic compounds. The technology and machines permit customers to efficiently mass produce heat exchanger stacks.

There is also a great demand for the LASERVORM expertise in many other branches, for example, when it comes to the processing of components used in automobile and machine construction, equipment and apparatus engineering as well as medical technology.

LASERVORM GmbH, Altmittweida