From shared kitchen to hidden champion of the chip industry

aSpect Systems GmbH in Dresden proves that innovation is not the domain of semiconductor companies. The 30-strong team is closing a gap in the European market to secure the last mile of chip production. This is where the final quality control of complex and special circuits takes place.

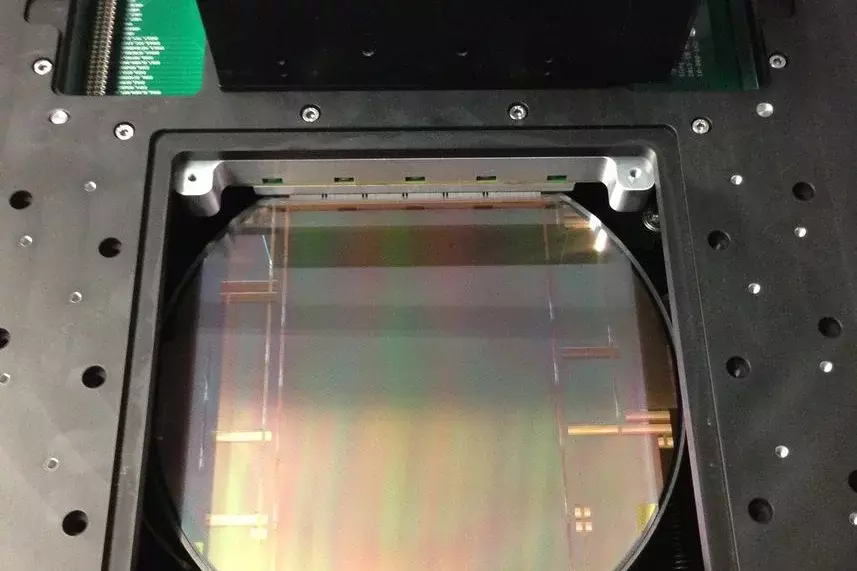

aSpect Systems is part of AEMtec from Berlin. aSpect is hidden away in an old brick building in the disused Leipzig railroad station in Dresden. Behind the walls is a 260 square meter clean room, high-tech measurement technology and robots that carry out technological steps that Europe actually lost to Asia decades ago: After wafer production by any foundry, the wafers are first tested and after final assembly at AEMtec in Berlin, the final quality control of circuits takes place in Dresden.

The agile team specializes in custom-made products, small series and particularly complex engineering projects that would be too complicated and unprofitable for the huge back-end factories in the Far East. Here in Dresden, the final, decisive steps are taken to turn a large silicon wafer into a flawless, usable electronic component. For example, the company develops imaging electronics on behalf of customers, characterizes customer wafers and takes care of prototype construction.

For example, aSpect Systems processes and tests chips for electron microscopes, lithography systems and large detectors for X-ray machines. Some of the circuits are smaller than a crumb of potato chips, others are as big as an XXL plate of pasta. The development of automated defect detectors supported by artificial intelligence (AI) is also one of their specialties. The company's product portfolio is unique in Europe, emphasizes Marcus Verhoeven, Managing Director of aSpect Systems alongside Robert Giertz and Philipp Gottesleben.

The story behind it is similar to the stories of Silicon Valley garage companies: Gottesleben and Verhoeven identified a gap in the market in a shared kitchen and founded their own company in 2003. From this pioneering era, aSpect Systems grew steadily and won numerous technology companies as customers. An important milestone in the company's recent history was the merger with the AEMtec Group in 2024. This strategic partnership combines AEMtec's global reach and expertise in advanced packaging with aSpect Systems' technical expertise in the semiconductor test environment.

For the aSpect team, Dresden Neustadt is exactly the right location for high-tech projects - the right place to design and experiment. A fitting statement for a company that, far removed from glossy facades, proves that true innovation can come from passion, expertise and the courageous decision to set up your own company in a shared kitchen.

aSpect Systems GmbH, Dresden