Fraunhofer Dresden: Design solar films for house facades

As part of the Design-PV project, the Fraunhofer Institute for Electron Beam and Plasma Technology FEP has made progress in the development of aesthetically pleasing solutions for building-integrated photovoltaics.

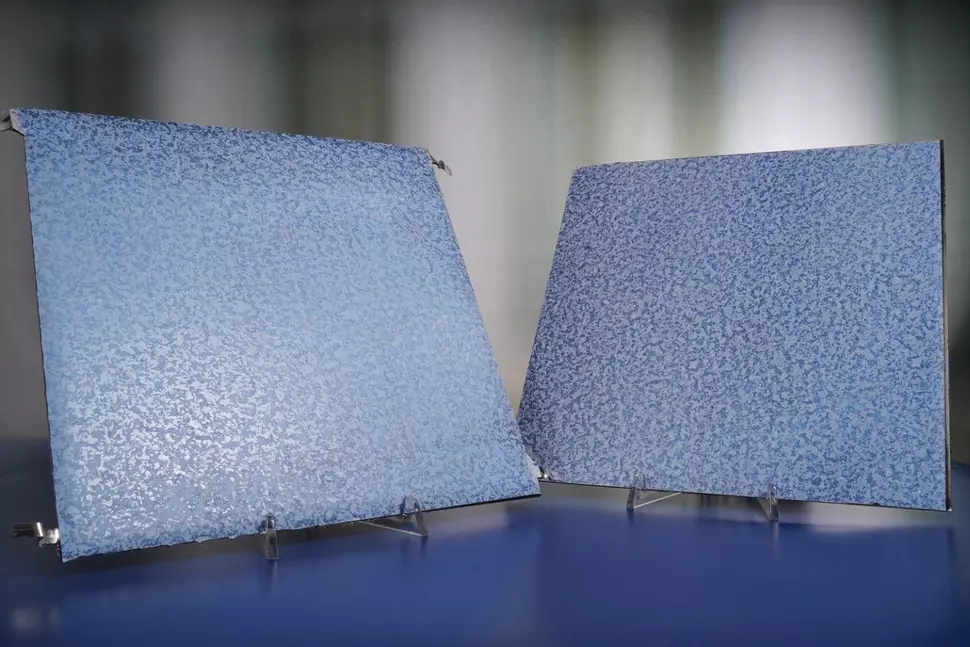

Initial tests show that the modules look almost indistinguishable from conventional façade elements and yet offer high energy efficiency.

Photovoltaics is a central pillar in achieving the goal of climate neutrality by 2045. Building-integrated photovoltaics (BIPV) offers an opportunity to use previously unused areas to provide energy. However, in order to increase the acceptance and spread of BIPV, PV modules must be integrated into the façade in a cost-effective, durable and visually appealing way.

The "Design-PV" project, funded by the German Federal Ministry for Economic Affairs and Energy, is working on precisely this. Together with five partners, the Fraunhofer FEP is developing decorative films for façade elements that are finished using roll-to-roll nano-imprint lithography (NIL). The aim is to achieve a uniform design on metal façade elements and photovoltaic modules by applying the decorative films to these elements. At the halfway stage of the project, the Institute for Solar Energy Research GmbH Hameln (ISFH) was able to apply and test several Surteco GmbH decors on PV-active and non-active façade elements.

"Tests by our project partner ISFH show that the PV modules with decors can hardly be distinguished visually from conventional façade elements and - depending on the decor - achieve an output of up to 80 % of the uncovered comparison modules," says Dr. Steffen Günther, project manager at Fraunhofer FEP. This represents significant progress, as aesthetic aspects are often seen as an obstacle to the acceptance of BIPV solutions.

A particular challenge in the project is the adhesive strength of the decorative films on the front glass of the PV modules as well as on the metal layer of the façade elements. In addition, the decorative coating must adhere reliably to the ETFE (ethylene tetrafluoroethylene) film substrate, which is already established in architecture due to its excellent weather resistance. However, as ETFE has low surface adhesion, it is necessary to specially treat the films before coating. A plasma process was developed at the Fraunhofer FEP for this purpose, which roughens the boundary layer of the ETFE film on a nanometer scale and thus significantly improves the adhesion of the decorative layers.

The next steps in the project include the testing of further decors and colors as well as comprehensive tests on the long-term stability and weather resistance of the developed solutions. The Fraunhofer FEP and its project partners are confident that these advances will help to further increase the acceptance of BIPV solutions in architecture.