BMW Leipzig: World's first hydrogen pipeline connection in car production soon

The BMW Group plant in Leipzig is planning to connect the site to a hydrogen pipeline. The plant is thus setting the course to become the world's first automobile production site to be supplied with hydrogen via a pipeline.

The contract has now been signed with the partners MITNETZ GAS GmbH and ONTRAS Gastransport GmbH. BMW has commissioned MITNETZ GAS with the construction of an approx. 2 km long connection pipeline from the plant to the future hydrogen core network, including a gas pressure control and measuring system. BMW and ONTRAS agree on the corresponding grid connection. The connecting pipeline will supply the plant with hydrogen from mid-2027.

In future, the pipeline will replace hydrogen deliveries by truck in pressurized cylinders. "By supplying hydrogen via a pipeline, we will be able to use hydrogen in completely new dimensions in the future. This applies in particular to our energy-intensive processes such as the dryers in the paint shop," emphasizes Petra Peterhänsel, Head of BMW Group Plant Leipzig.

A fuel-flexible burner was put into operation in the paint shop at the BMW plant in Leipzig for the first time worldwide in October 2022. As of today, a total of eleven bivalent burners are installed in the paint shop. These can flexibly burn natural gas or hydrogen.

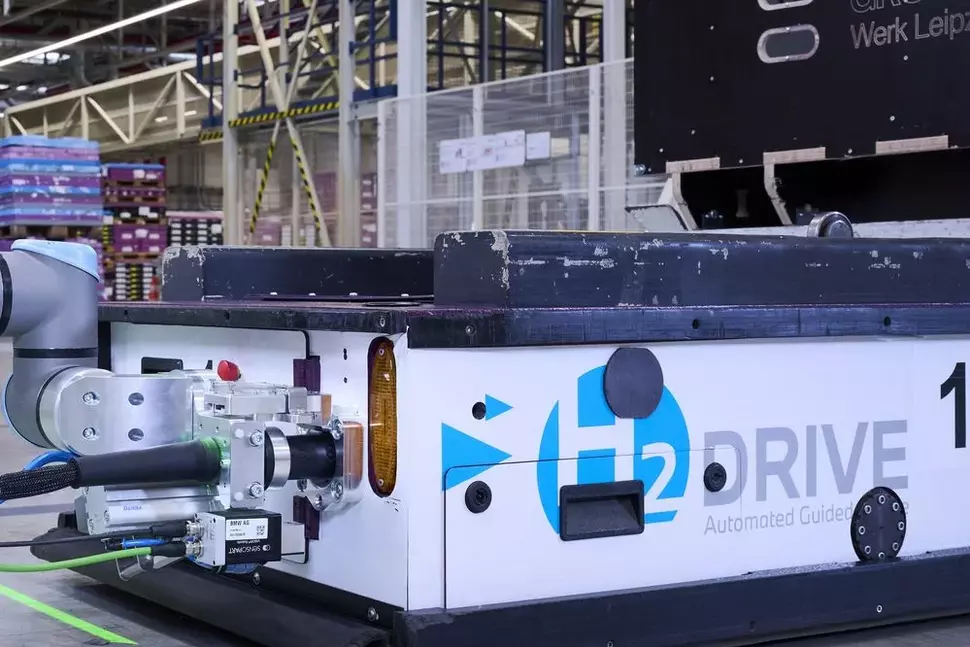

In addition, the Leipzig plant has been using forklift trucks and tugger train tractors with hydrogen fuel cell drives in intralogistics since 2013. The fleet at the site now comprises over 230 such vehicles, making it the largest in Europe. These are refueled at nine hydrogen filling stations in the factory halls.

The hydrogen core network is an infrastructure of around 9,000 kilometers of hydrogen pipelines planned throughout Germany. This is to be gradually put into operation by 2032 in order to connect Germany to the supra-regional hydrogen network.