Sensitive and Extra Strong

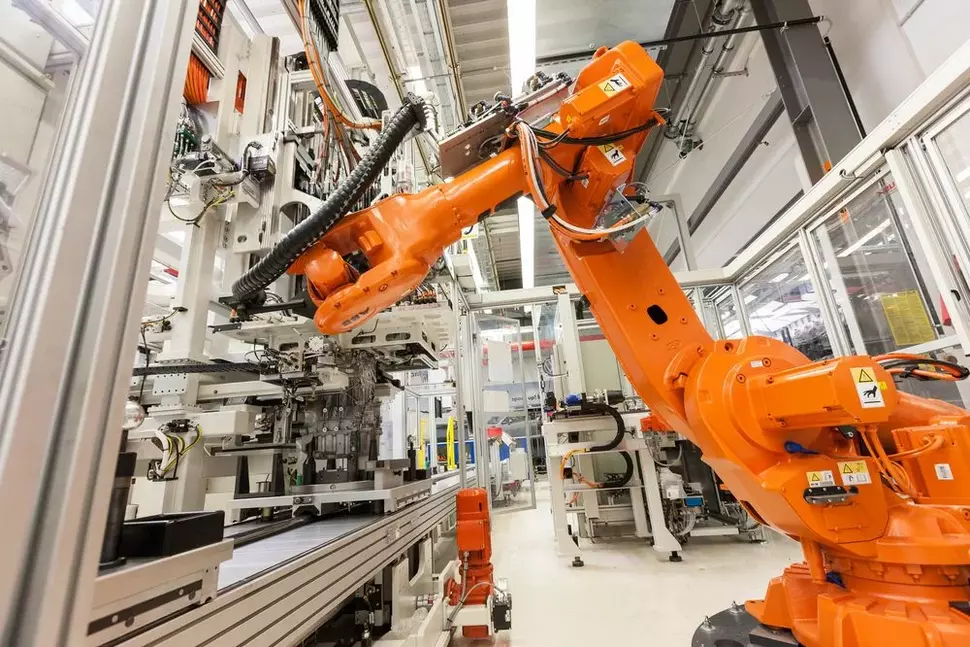

They can insert tiny little contacts into injection molding machines with utmost dexterity and position heavy components with pinpoint accuracy for the precision assembly of utility vehicle axles: Robotics solutions made by Aumann Limbach-Oberfrohna.

Robotic solutions from Aumann Limbach-Oberfrohna GmbH move parts weighing between five grams and 200 kilograms precisely to the desired processing cycle. The systems are used in factories around the world. They are used to manufacture sensors, electric motors or photovoltaic modules, for example, and to assemble battery systems, brake boosters or hybrid transmissions. Well-known automotive manufacturers and suppliers are among the company's long-standing customers, as are clients from the renewable energy and electronics sectors.

Aumann engineers and specialists design, manufacture and integrate robotics applications, particularly in industrial processes in which a high product variance must be handled flexibly and efficiently - from parts feeding to joining and assembly processes through to the removal of assemblies.

Precise programming for quick and easy retooling is a key criterion for the design of the systems. The expertise gained from robotics integration flows into the project planning and realisation of complete assembly and handling systems. The Saxon company of Aumann AG is strengthening its activities in the field of new mobility such as battery electric and fuel cell systems as well as production technology for automated driving components.

Aumann Limbach-Oberfrohna GmbH