Strong Industries

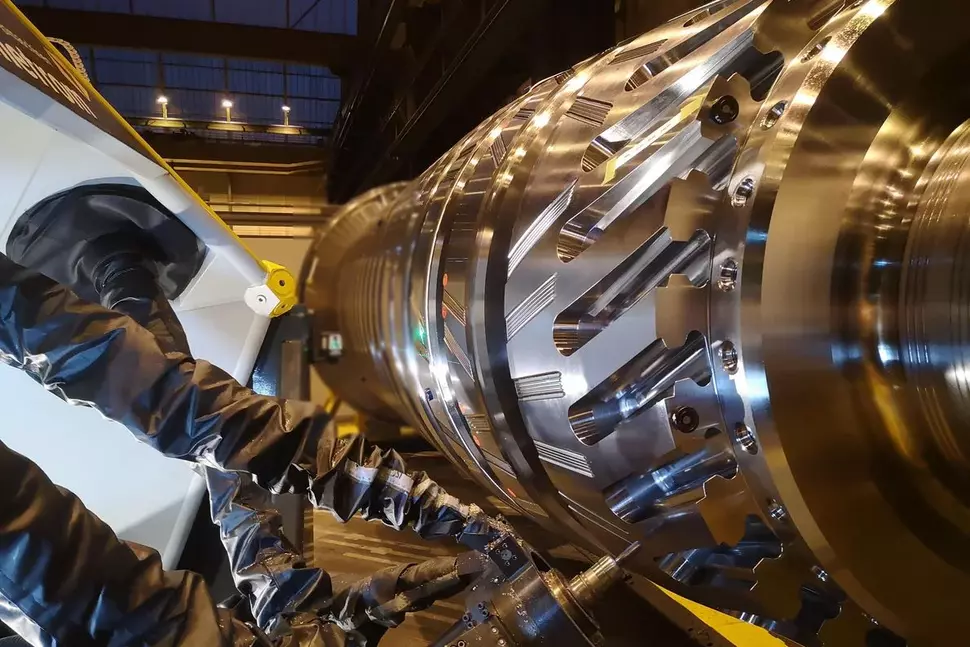

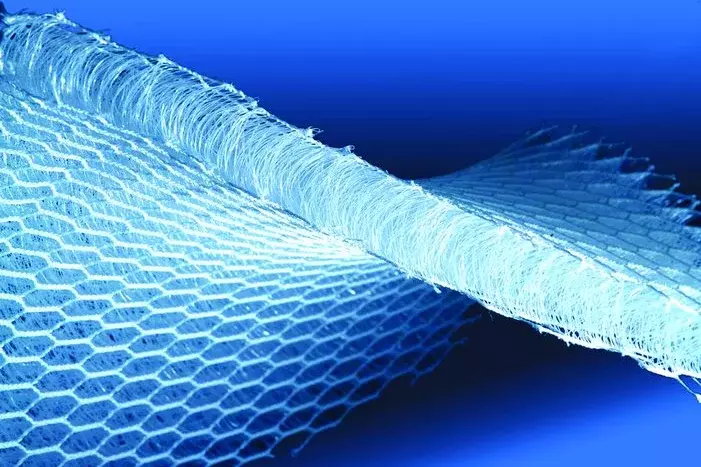

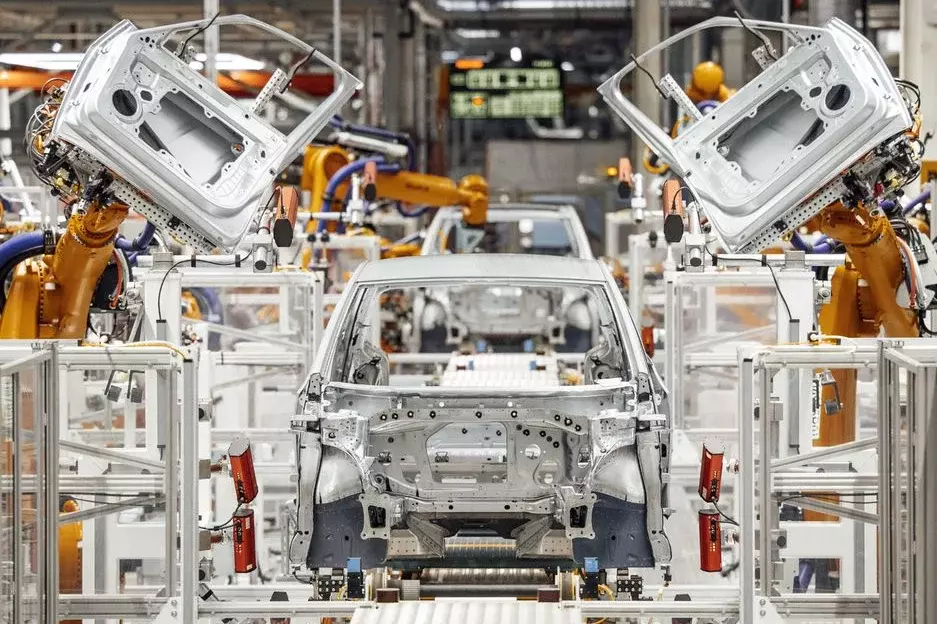

... form the backbone of Saxony as a business location. Whether mechanical engineering, the railroad industry, the healthcare sector or "Autoland Saxony" and "Silicon Saxony" - smart ideas and intelligent solutions have given rise to powerful industries.

Infomodul

Facts About Saxony's Industry (2024)

-

82,385 million €

total turnover of Saxony's industry -

33,055 million €

export turnover (industry) -

40.1 %

export quota (industry)

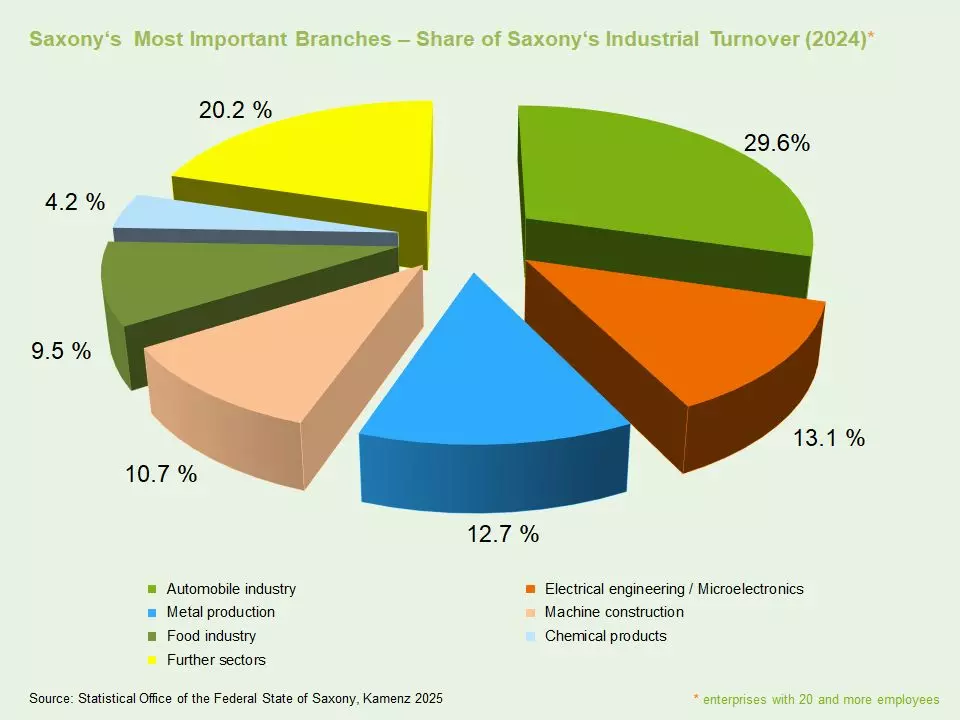

Share of Key Sectors in Saxony's Industry Turnover (2024)

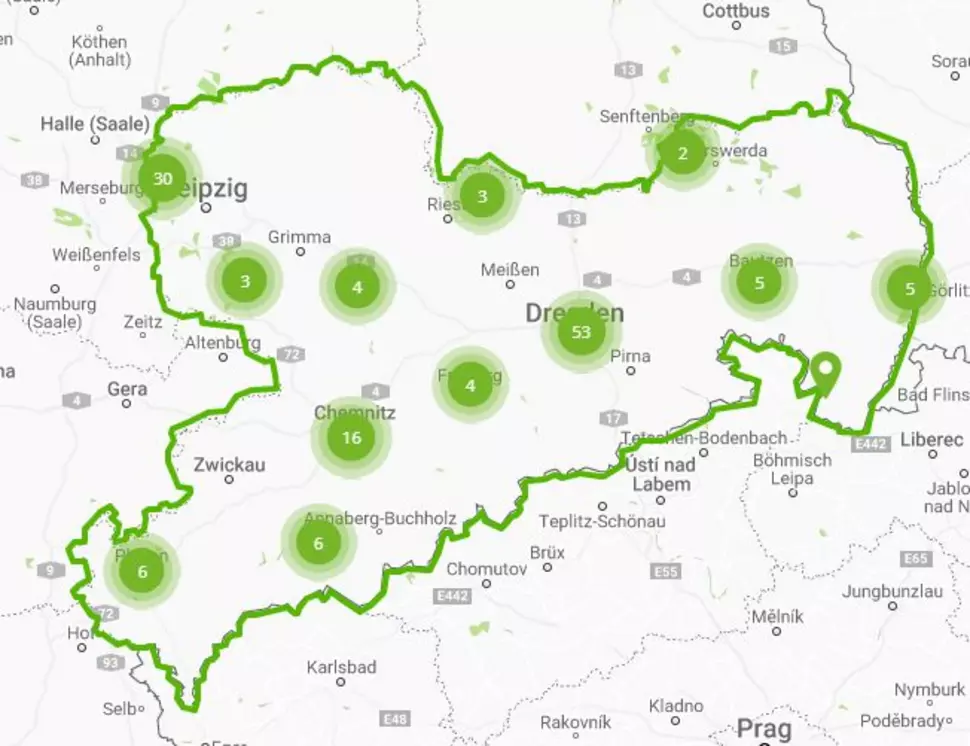

The most important industrial sector in Saxony, with a 29.6% share of turnover, is the automotive industry. This is followed by the electrical engineering / microelectronics and metal production sectors with 13.1% and 12.7% respectively, as well as mechanical engineering with 10.7% of Saxony's industrial turnover.

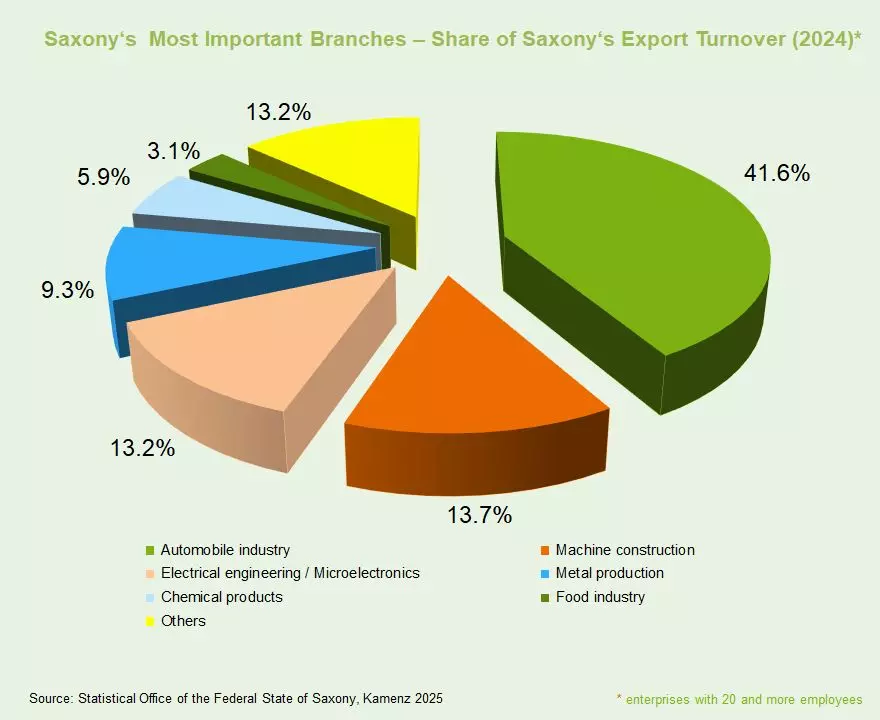

Share of Key Sectors in Saxony's Export Turnover (2024)

With a 41.6% share of foreign sales, automotive industry products are Saxony's most important export products. As in previous years, the four economic sectors of automotive, mechanical engineering, electrical engineering and metal production / processing generate more than three quarters of industry's foreign sales.

Contact

Dr. Uwe Lienig

Industry, Innovation & Marketing

+49-351-2138 201

Andreas Lippert

Investor Services

+49-351-2138 211