Autoland Saxony

With six vehicle, engine and battery plants operated by Volkswagen, BMW, Mercedes-Benz and Porsche, "Autoland Saxony" is one of the top 5 automotive locations in Germany. Every eighth car and 40% of all fully electric cars built in Germany are "Made in Saxony".

Infomodul

Facts About "Autoland Saxony" (2024)

-

815

suppliers -

95,000 (80%)

employees (of that in the suppliers sector) -

29.6 %

share of Saxony's industrial turnover -

41.6 %

share of Saxony's export turnover

Automotive Engineering Networks

The networks in "Autoland Saxony" have played a significant role in ensuring that the predominantly medium-sized Saxon automotive suppliers have mastered the ABC of supplier management, are up to the current challenges of the industry and have found their place in the global automotive value chains.

AMZ unites over 160 members from the most diverse areas of the automotive value chain: research and development, mechanical engineers and equipment manufacturers, suppliers and service providers.

Automotive Supplier Network Saxony (AMZ)

Since 2004, ACOD has been the initiative and joint action platform of automobile manufacturers, suppliers and service providers, research institutes, associations and institutions active in Berlin / Brandenburg, Mecklenburg-Western Pomerania, Saxony, Saxony-Anhalt and Thuringia.

Automotive Cluster Ostdeutschland (ACOD)

As Saxony's competence center for hydrogen and fuel cell technologies for the mobility of the future, HZwo e. V. supports its partners in considering this future field across the entire value chain.

HZwo e. V.

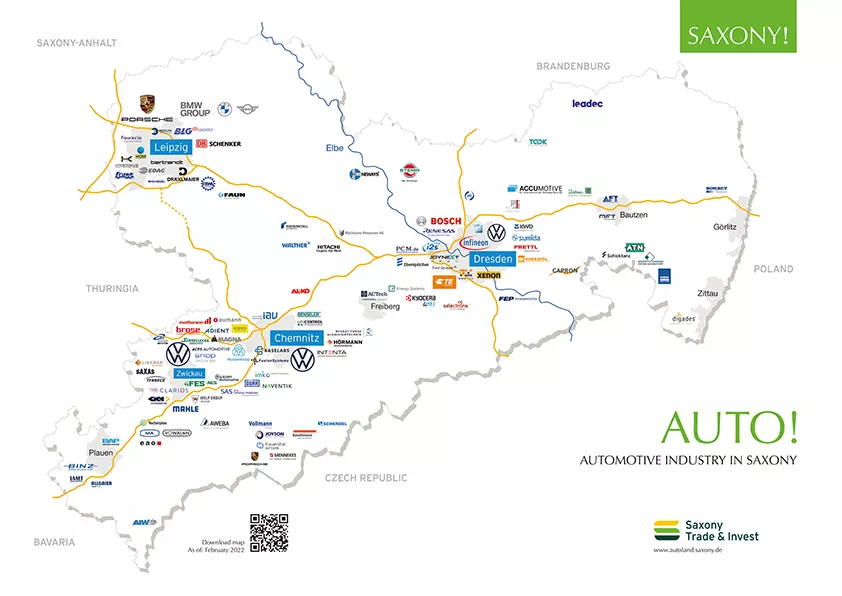

Overview Map

Selected companies in the automotive industry in Saxony and regional focuses

Do you have any questions? Then contact our industry experts.

Dr. André Günther

Industry, Innovation & Marketing

+49-351-2138 242

Falk Becher

Investor Services

+49-351-2138 151